Our Products

Engineered with Accuracy. Built for Performance

At SLP Engineers, we manufacture a wide range of high-precision components and mould bases, customized to meet the needs of industries that demand exacting standards. From die casting to defense, and from small batch prototypes to large-scale production, our products are designed to deliver consistency, strength, and reliability in every application.

With over two decades of experience and advanced CNC machining capabilities, we are your one-stop destination for custom-engineered components tailored to your specifications.

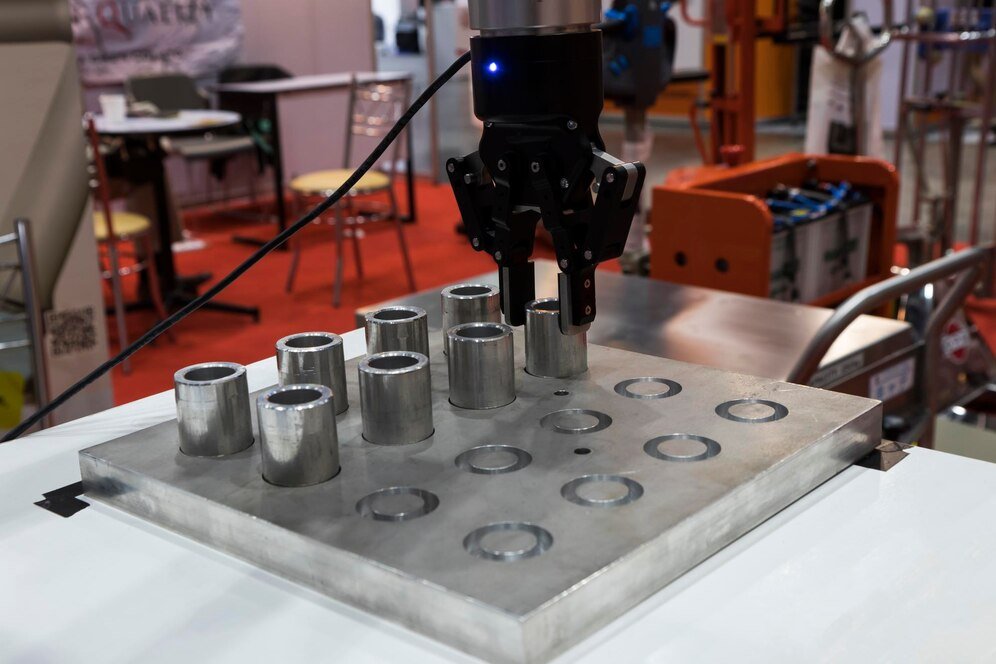

Mould Bases

The Foundation of Precision Tooling

Our mould bases are trusted by manufacturers in the die casting, plastic injection moulding, and compression moulding industries. Built with hardened tool steel and machined on 4-axis VMCs, our mould bases guarantee high dimensional accuracy, ease of assembly, and long service life.

Types of Mould Bases We Offer:

HPDC (High-Pressure Die Casting) Mould Bases

LPDC (Low-Pressure Die Casting) Mould Bases

Injection Moulding Mould Bases

Compression & Transfer Mould Bases

Custom Mould Bases with Cooling & Ejection Features

Key Features:

Tolerance up to ±0.01 mm

Machined flatness and squareness

Corrosion and wear-resistant surfaces

Ready-to-assemble with precision holes and slots

Die Casting Spare Parts

Critical Components for High-Performance Casting

We manufacture a wide range of die casting tool parts and accessories that ensure smooth and reliable casting operations. Designed for compatibility with a variety of moulds and systems, our parts are built for durability, thermal resistance, and high cycle life.

Common Components Include:

Sliders

Side Cores

Plunger Bushes

Spreader Plates

Guide Pillars, Bushes, and Pins

Applications:

Aluminum, zinc, and magnesium die casting tools in automotive and industrial applications.

Aerospace & Missile Components

High-Spec Parts for High-Stakes Applications

SLP Engineers is trusted by aerospace and defense clients for producing flight-grade components and mechanical subsystems. Manufactured under tight tolerances and strict process controls, these parts are used in critical assemblies that demand uncompromising quality.

Our Capabilities Include:

Aerospace Sliders

Missile System Sub-Assemblies

Precision Brackets, Supports, and Plates

Structural & Load-Bearing Components

Why Choose Us for Aerospace:

Reliable dimensional repeatability

Custom packaging and traceability

Compatible with aerospace-grade materials and alloys

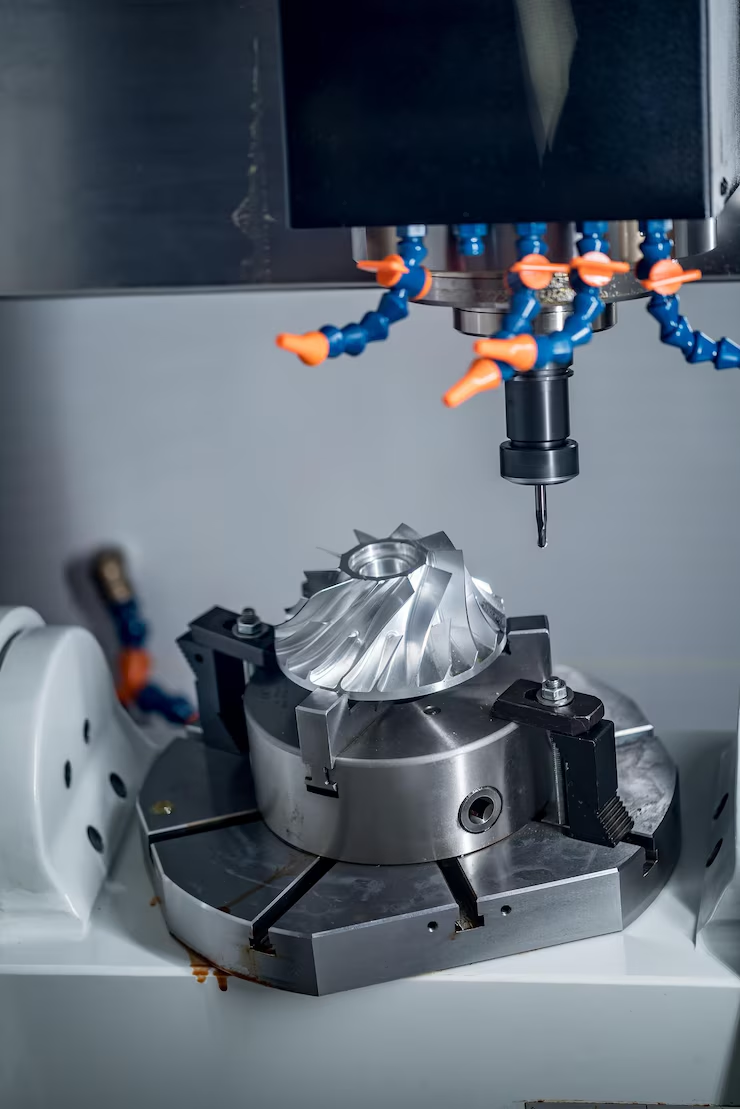

Custom Machined Components

From Drawing to Delivery—100% Customized

We understand that off-the-shelf solutions don’t always work. That’s why we offer fully custom machining services, building parts exactly to your design requirements, no matter the complexity or volume.

We Support:

One-off prototypes and sample runs

Batch production with consistency

Reverse engineering from physical samples

Materials We Work With:

Tool Steel, Alloy Steel

Stainless Steel, Mild Steel

Aluminum, Copper, Brass, Bronze

Engineering plastics (on request)