Our Services

Precision Engineering Solutions Tailored to Your Industry

At SLP Engineers, we combine 20+ years of expertise, cutting-edge CNC machinery, and a commitment to quality to deliver end-to-end precision engineering services. From custom mould base manufacturing to aerospace-grade components, we provide complete solutions designed to meet the highest standards in automotive, aerospace, defense, power, and tooling sectors.

Mould Base Manufacturing

Built to Perform. Engineered to Last.

We manufacture a wide variety of custom mould bases designed for multiple moulding and die casting applications. Whether you require compact bases or large, multi-cavity systems, our mould bases ensure dimensional stability, structural rigidity, and operational efficiency.

We provide:

HPDC (High Pressure Die Casting) Mould Bases

LPDC (Low Pressure Die Casting) Mould Bases

Injection Moulding Mould Bases

Compression & Transfer Mould Bases

Customized Sizes with Cooling, Ejection, and Alignment Systems

Features:

Precision-machined surfaces

Hardened steel or custom alloys

Tolerance up to ±0.01 mm

CAD/CAM design support included

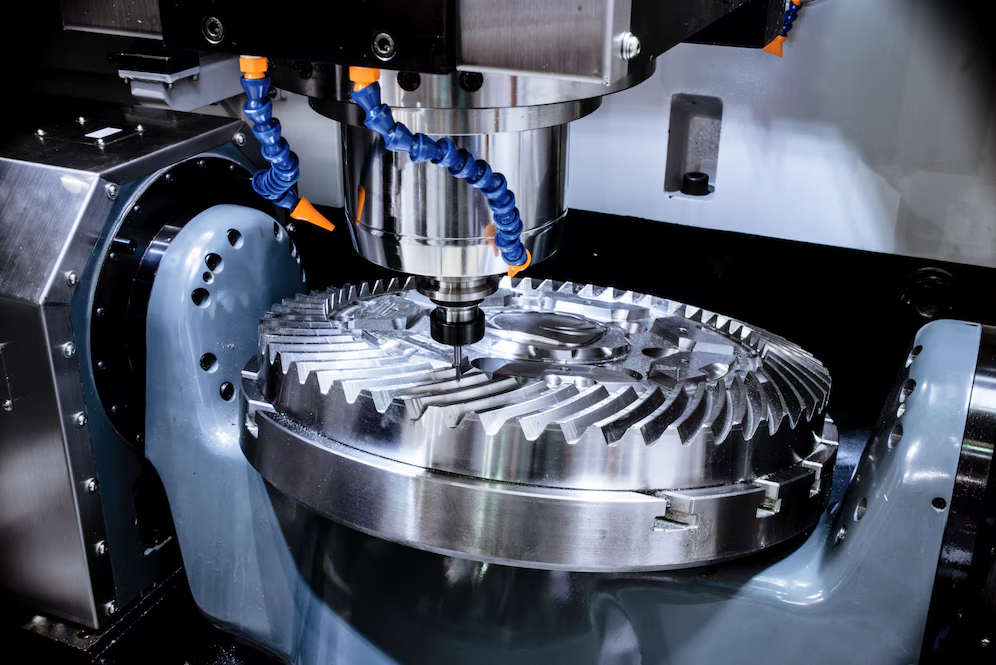

Custom Component Manufacturing

From Blueprint to Precision Product

We specialize in machining complex parts from customer-provided designs. Whether you need high-accuracy components or niche tools for die casting, we can produce parts with tight tolerances and surface finishes that meet global standards.

We manufacture:

Sliders, Side Cores

Plunger Bushes, Spreader Plates

Aerospace and Missile Components

Die Inserts, Bushes, Guides

Capabilities:

4-Axis CNC Machining

Low to high-volume production

Multiple materials including tool steel, stainless steel, aluminum, and brass

Sub-Assembly & Integration Services

We Don’t Just Machine—We Assemble

We go beyond machining by offering sub-assembly and integration services for clients who require functional units, not just individual parts. Every assembly is tested for fit, function, and durability before shipment.

Applications:

Aerospace mechanical assemblies

Defense integration modules

Die casting tool assemblies

Benefits:

Reduced vendor management

Faster deployment

Precision fit and finish guaranteed

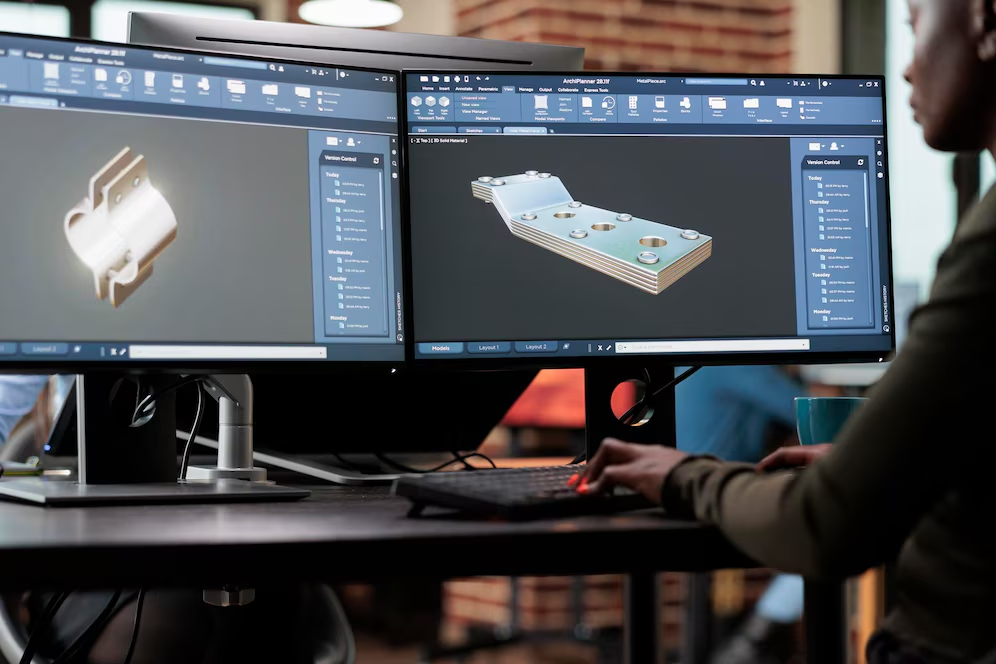

Design & Engineering Support

Collaborative Design for Efficient Manufacturing

Our in-house engineers work with your team to convert ideas into manufacturable components. Whether you have a complete CAD model or a basic concept, we offer full design optimization to enhance performance and reduce cost.

Services include:

CAD/CAM Design & Drafting

Reverse Engineering

Prototyping & Simulation

2D to 3D Conversion (DWG, IGES, STEP)

Tool Room & Job Work Services

Quick Turnaround. Exceptional Precision.

With our modern tool room setup, we undertake custom machining jobs ranging from prototyping to repair and rework. Our machines handle small to large components with accuracy and repeatability.

We handle:

Rapid prototyping

Jigs & fixtures manufacturing

Component rework & modification

Precision slotting, boring, grinding, and drilling

Quality Control & Inspection

Every part that leaves our facility is quality-tested at every stage of production. We use calibrated tools, visual inspections, and in-process QC to ensure parts are defect-free and match customer specifications.

Quality Measures Include:

Dimensional inspection reports

Visual & functional testing

Material traceability

Export-grade packaging